The establishment of an electrical appliance traceability system provides the electrical appliance industry with efficient product quality and safety management solutions through traceability labels and data visualization.

With the rapid development of the electrical industry, product quality and safety issues have attracted much attention. In order to improve the quality and safety of electrical products, it is imperative to establish a complete traceability system. The electrical traceability system can achieve full management and traceability of the product life cycle through traceability labels and data visualization, thereby effectively solving the problem.

1. Application of traceability labels

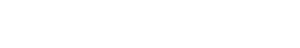

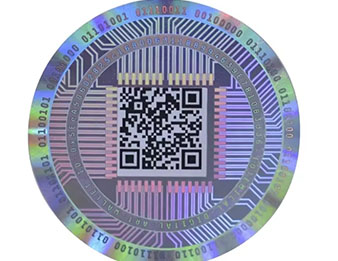

During the production process of electrical appliances, each electrical product can be attached with a unique traceability label. The label contains key information such as the basic information of the product, production date, and production process. By scanning the QR code on the traceability label or reading the RFID label, you can quickly obtain detailed information about the product and trace the product.

2. Data visualization management

By integrating the traceability label information into a data platform, the management and traceability of the entire product life cycle can be achieved. The platform can record data from all aspects of the product from raw material procurement to production and processing, factory circulation, sales and after-sales. Enterprises can analyze and mine data through the data platform, discover product quality problems in a timely manner, and take corresponding measures to improve them.

3. Reduce risks and enhance trust

The electrical traceability system of Zhengmaomao can help enterprises reduce risks and enhance consumers' trust in their products. If a product has quality problems, the company can quickly locate the specific affected product batches through the traceability system, take corresponding recall and handling measures, and avoid causing greater losses to consumers. At the same time, through the establishment of a traceability system, the company can establish a good product quality and safety management image and enhance consumers' trust in the company.

IV. Application scenarios

The electrical appliance traceability system is widely used in all aspects of the electrical appliance industry. In the raw material procurement link, the management and monitoring of suppliers can be achieved to ensure the quality and safety of the products. In the production and processing process, the operator and equipment information of each link can be traced to ensure that the production process meets the quality requirements. In the sales and after-sales section, it can help companies to conduct product feedback and customer service management and improve user experience.

The establishment of an electrical appliance traceability system is of great significance to ensure product quality and safety. Through traceability labels and data visualization, companies can achieve full management and traceability of the product life cycle, timely discover and handle problems, and enhance consumers' trust in the company. As a traceability system technology company, Zhengmaoma provides efficient product quality and safety management solutions for the electrical appliance industry, helping the sustainable development of the electrical appliance industry.